History

The story of WSP is the story of an ambitious programmer who grows into an entrepreneur. His toolbox grows into a complete business. What remains are innovativeness and decisiveness. Check the facts.

1993 - Establishment of WSP

Experienced control engineer Maarten Ploeg founded Laundry Service Ploeg (WSP) because he wants to focus exclusively on automating laundries.

2001 – WinWash®

Production visualisation was initially realised with Unix operating systems and industrial terminals. With the advent of Windows, our professionals soon switched to programming in Windows and Visual Basic environments. The result: WinWash®. Today, WinWash® is a familiar name. It is the brain of the laundry and controls the logistics and production processes of more than 200 laundries worldwide.

2010 - Acquisition of production facility in Germany

Since the company was founded, suspended conveyor systems and conveyor belts were purchased. In 2010, WSP decided to start producing internal logistics systems in-house. The main motivation was to gain more control over quality, cost price and delivery reliability. To achieve this, WSP acquired a complete overhead conveyor production facility, including personnel, from Lavatec in Sarstedt, Germany.

2012 – Establishment of Laundry Dashboard®

Demand from the market grew for an easy way to collect useful information at operational, tactical and strategic levels and make it available to both production staff and management. In response, WSP launched the management tool Laundry Dashboard® in 2012.

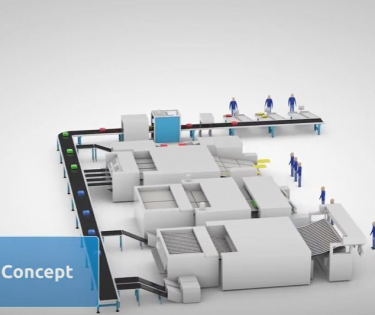

2016 - WSP concepts

In 2016, WSP decided to also offer integrated solutions in the form of concepts. These concepts combine conveyor systems, controls, and interfacing with other systems in the laundry. With its software, systems and services, WSP is perfectly placed to act as a system integrator, offering and integrating a total concept.

2017-2019 - Investing in development

From 2017 to 2019, WSP has focused on investing in the development of WinWash® 2.0, Laundry Dashboard® 2.0 and Smart Customisation. Smart Customisation makes it possible to build customer-specific solutions with as many standard components as possible. So the usual high quality at a competitive price.

2025 - Objective: the laundry of the future

WSP has a clear goal for the laundry of the future. The laundry in 2025 has reduced its share of labour costs by 40%, machine utilisation is 90% and productivity per m2 has increased by 20%. Productivity and cost reduction are crucial for competitiveness. The logistics process makes the difference between profit and loss. Customer processing order, completeness checking and priority are dynamically controlled and adjusted. WSP makes this possible by controlling the entire supply chain with WinWash® and Laundry Dashboard®.

1999 - In-house manufacturing of conveyor systems

WSP designs and builds its first conveyor systems. Many of the early conveyors still prove their value to our customers.

2008 - Building new offices

WSP's new headquarters will be located in the rural surroundings of Overberg. From there, global customers will be served and supported with 24-hour support.

2011 – Change of name

After 18 years, the company name was changed to WSP Systems BV. With an increasingly international clientele, the new name was more appropriate. Moreover, the word 'systems' clearly reflects the nature of WSP's services.

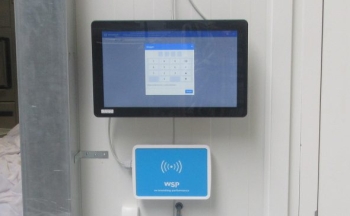

2015 - Full UHF RFID integration

In recent years, WSP has been experimenting drily with RFID technology and partial solutions. In 2015, WSP realised the first personal laundry where UHF RFID technology was applied from start to finish.

2018 - New production facility

Due to continued expansion, the specialist in internal logistics operations, grew out of size and in April 2018, WSP Systems moved into a second production facility in Amerongen. Here, production of all hardware components, such as conveyors and overhead conveyor systems, takes place under one roof and can be easily tested and displayed for the benefit of customers.

2021 – WSP 2.0

To move to the next level, a lot of energy has been put into the design of 'WSP2.0'. An updated organisation chart, new structures and project flows are being set up to ensure further professionalisation and a solid foundation for future growth plans.