Renewal of logistics controls at Urzinger Textilmanagement

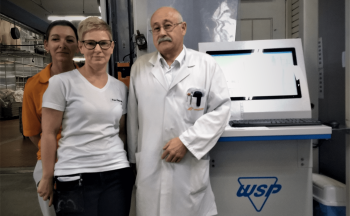

In southern Germany, in the city of Landshut, WSP has implemented a beautiful project for the laundry company Urzinger Textilmanagement. This project consisted of the replacement of various logistic controls. The controls on the unclean side (sorting system and overhead conveyor) as well as on the clean side (terry and work clothes overhead conveyor) have been completely renewed. By using WinWash® 2.0, the logistics process is now fully automated and optimized at the same time.

In southern Germany, in the city of Landshut, WSP has implemented a beautiful project for the laundry company Urzinger Textilmanagement. This project consisted of the replacement of various logistic controls. The controls on the unclean side (sorting system and overhead conveyor) as well as on the clean side (terry and work clothes overhead conveyor) have been completely renewed. By using WinWash® 2.0, the logistics process is now fully automated and optimized at the same time.

WSP realized this over only two weekends, fully within the estimated timeframe. The customer was able to continue production on Monday morning without delay, but now with WSP control and logistics.

As with many laundries, also at Urzinger Textilmanagement, there is often the possibility of further automation and increased performance. This is exactly what WSP as a system integrator focuses on. By integrating and fully automating the entire logistics chain, the productivity of a laundry can be significantly improved. At Urzinger Textilmanagement, WSP also achieved this to the great satisfaction of our customer. Thanks to our in-house expertise and innovations, such as WinWash® 2.0, we offer our customers the opportunity to continuously achieve top performance. We always work with you to see how we together can improve your performance.